The viscosity of the lubricant has a great influence on the performance and service life of the machine. By choosing a lubricant with the proper viscosity index for your application, you can minimize downtime and maintenance costs.

A lubricant's viscosity is actually its resistance to flow and shear. It is affected by factors such as contamination by water, particles or other lubricants, but also oil aging can affect viscosity.

Two common types of viscosity are kinematic viscosity and dynamic viscosity. Dynamic (or absolute) viscosity provides information about the force required to make a lubricant flow, while kinematic viscosity indicates how fast a lubricant will flow when force is applied. The unit of dynamic viscosity is millipascal second (mPa·s) or equivalent centipoise (cP), while the unit of kinematic viscosity is square millimeter per second (mm²/s) or equivalent centistoke (cSt).

What is the viscosity index (VI) of a lubricant?

The viscosity of a lubricant is affected by temperature: the higher the temperature, the lower the viscosity. The formulation and quality of the lubricant determine how much viscosity decreases with increasing temperature.

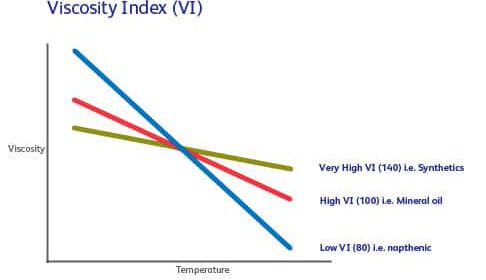

The viscosity index (VI) of a lubricant is the rate of change in viscosity due to temperature changes. To know whether a lubricant meets the requirements of an asset based on its operating temperature range, you must understand VI.

How to determine the viscosity index of a lubricant?

The viscosity index of a lubricant is determined by measuring the kinematic viscosity at 40°C and 100°C. These measurements are then compared to the results of two reference oils.

Conventional mineral oils have a viscosity index between 95 and 100. Highly refined mineral oils (hydrotreated) can have a VI as high as 120. Hydrocracked base stocks have a VI greater than 120, while synthetic oils may have a higher VI.

Viscosity Index Chart

In the graph below you can see how the viscosity (vertical axis) of two different lubricants varies with temperature (horizontal axis). Lubricants with a high VI have a more horizontal slope: the viscosity remains more stable over a wider temperature range.

This means that a lubricant with a higher viscosity index is more preferred because it provides a more stable lubricating film over a wider temperature range.

Risks of Low VI Lubricants

Oils with a lower viscosity index may have the right viscosity at a particular temperature, but their viscosity drops dramatically as the temperature rises. This leads to increased mechanical friction and wear due to film loss.

At lower temperatures, the viscosity of low VI lubricants can be too high, resulting in low oil flow, oil starvation and dry starts.

Always check the VI of the lubricant

To increase the viscosity index, manufacturers can enhance lubricants with certain additives. This allows lubricants to be formulated to meet OEM specifications.

When selecting a lubricant for your application, we always recommend that you review the equipment manufacturer's specifications. You must consider the climate and operating conditions of the machine.

By choosing the right lubricant with the correct VI, your machinery will perform better and last longer.

HDM offers lubricants with high VI

Some examples of high VI products in the HDM product family are as follows:

The range of hydraulic oils is suitable for a wide range of temperatures and applications. Due to its very high viscosity index >180, this hydraulic oil has excellent flow characteristics. High oxidation stability ensures extended drain intervals and lubricant life.

A range of synthetic turbine oils specially developed for steam and gas turbines (and combined cycle applications). Due to its excellent oxidation and thermal stability, HDM is especially suitable for extreme operating conditions and high temperature gas turbine operation. Viscosity index >130, viscosity remains stable over a wide temperature range.