Selecting the proper grease is critical to maximizing application performance. While commonly quoted specifications give a general indication of which type of grease to use, they do not necessarily take into account all operating elements and parameters that affect system performance and efficiency. This article can help you choose the right grease for your specific application.

In many industries, grease specifications are described quite generically, for example: "NLGI (National Lubricating Grease Institute) n° 2 high quality", while in other cases OEMs specify lubrication by providing a branded product name and some additional information grease, such as DIN or ISO specifications.

Specific greases for every application

However, the range of petroleum products is extremely wide and varied, each with specific qualities that make it suitable for a particular application. Proper grease product recommendations require extensive knowledge of all relevant job elements:

- Operating temperature and conditions

- load status

- spinning speed

- application type

base oil viscosity

Most applications involve the lubrication of bearings. For these applications, the viscosity of the base oil is the most important parameter. Do not confuse this with NLGI-mandated conformance.

To calculate the minimum base oil viscosity you need to know the following parameters:

- Bearing mean diameter dm (mm)

- Bearing speed (rpm)

- Operating temperature (°C)

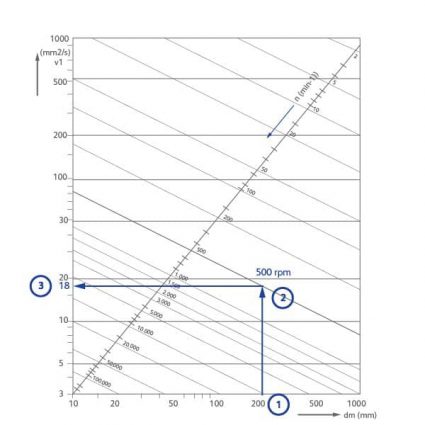

The chart below shows how to determine the minimum base oil viscosity for your application.

For example: the average diameter of the bearing is 200mm.

Speed 500rpm, working temperature 70°C

The first step: average diameter 200mm

Step 2: Speed: 500 rpm

Step 3: It defines the viscosity of the base oil at the time of operation

temperature => approx. 18 mm²/s

Step 4: 18mm²/s at 70°C, approx. 60 mm²/s at 40°C (follow the direction of the arrow)

How does bearing speed affect minimum base oil viscosity?

- Higher bearing speeds require lower viscosities

- Lower bearing speeds require higher viscosities

How does operating temperature affect minimum base oil viscosity?

- Higher operating temperatures require higher viscosities

- Lower operating temperature requires lower viscosity

How does average bearing diameter affect minimum base oil viscosity?

- Larger average bearing diameter requires lower viscosity

- Smaller average bearing diameter requires higher viscosity

Base Oil and Thickener Type

Greases are usually based on Group I and II mineral base oils. These greases are suitable for applications with operating temperatures up to 120°C. For applications with very low or high operating temperatures, use synthetic base stocks with PAOs or esters. These base stocks are also suitable for applications requiring extended oil drain intervals or requiring food grade certification and/or biodegradability.

In addition to base oils, thickeners also determine the basic structure of greases and divide them into different types. Different types of thickening soap and non-soap thickeners are used, each with its own specific properties. They can vary in the following ways:

- water resistance

- pumpability

- Dropping Point

- thermal stability

- mechanical stability

Soap-based thickeners can be divided into metallic soap-based thickeners (Li, Ca, Al...) and non-metallic soap-based thickeners polyurea, clay, silica gel, PTFE...)

| Performance property | Li | Hydrated Ca | Water free Ca | Li-Ca | Li-complex | Ca sulphonate | Ca complex |

| Thermal stability | good | Poor | Good | Good | Excellent | Excellent | Very good |

| Shear stab | good | Good | Very good | Good | Very good | Very good | Very good |

| Water resistance | good | Very good | Excellent | Very good | Good | Excellent | Very good |

| Load carrying capacity | good | Moderate | Good | Very good | Very good | Excellent | Excellent |

| Dropping point | Good | poor | good | good | excellent | Excellent | Very good |

Grease consistency

The NLGI grade is a measure of the consistency of a grease and is determined by the concentration and type of thickener and, to a lesser extent, the viscosity of the base oil. Greases are available in high consistency NLGI 3 and base oil viscosity of 40mm²/s. A liquid grease (NLGI 00) with a viscosity of 800 cst can also be used.

A good rule of thumb is to use a grease with a higher NLGI grade in higher speed applications.

The following table explains the different NLGI classes.

| NLGI Class | Penetration Number | Consistency at room temperature |

| 000 | 445-475 | Very liquid |

| 00 | 400-430 | Liquid |

| 0 | 355-385 | Semi-liquid |

| 1 | 310-340 | Very soft |

| 2 | 265-295 | Soft |

| 3 | 220-250 | Semi-solid |

| 4 | 175-2015 | Solid |

| 5 | 130-160 | Very solid |

| 6 | 85-115 | Extremely solid |

Grease properties

Once all the above parameters have been determined, the following properties of the grease will be used as selection criteria:

- Dropping point

-Water washout - Pumpability

-Environmental friendliness

These properties are mainly determined by the application conditions: water, extreme pressure performance, steam, temperature, food industry, biodegradability, harsh conditions...

For example, high-temperature grease is not necessary when the bearing operates primarily at ambient temperature. Lightly loaded high speed bearings do not require high performance extreme pressure additives.

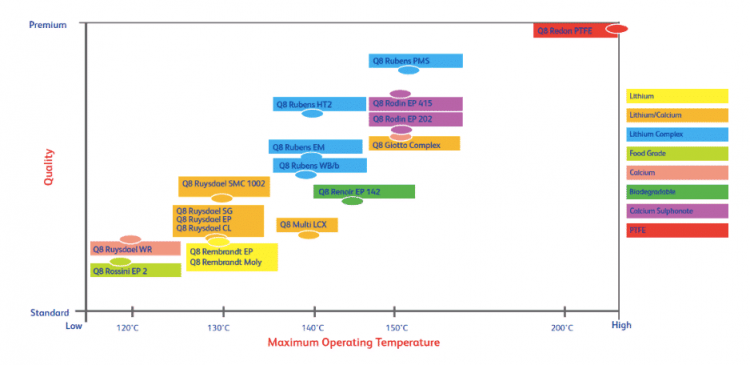

The following overview describes the performance of the Q8oils family of greases at operating temperatures.